Home

Factory rejects are products such as food production co-products, products with wrong label or packaging, products that do not meet your standards and/or are not suitable for the market or unwanted products coming free during a production process. Most of these products are mono stream (single stream) and can be separated very easily.

For example, cans with outdated fish, yogurt pots, chocolate bars or cutups that still contain some packaging. The factory rejects arrive in boxes, on pallets or in containers. With our extended experience in processing food waste, we have processed almost every food waste product in the market. Interested in a solution for your waste? Please send us a picture of your material so we can share our expertise/video.

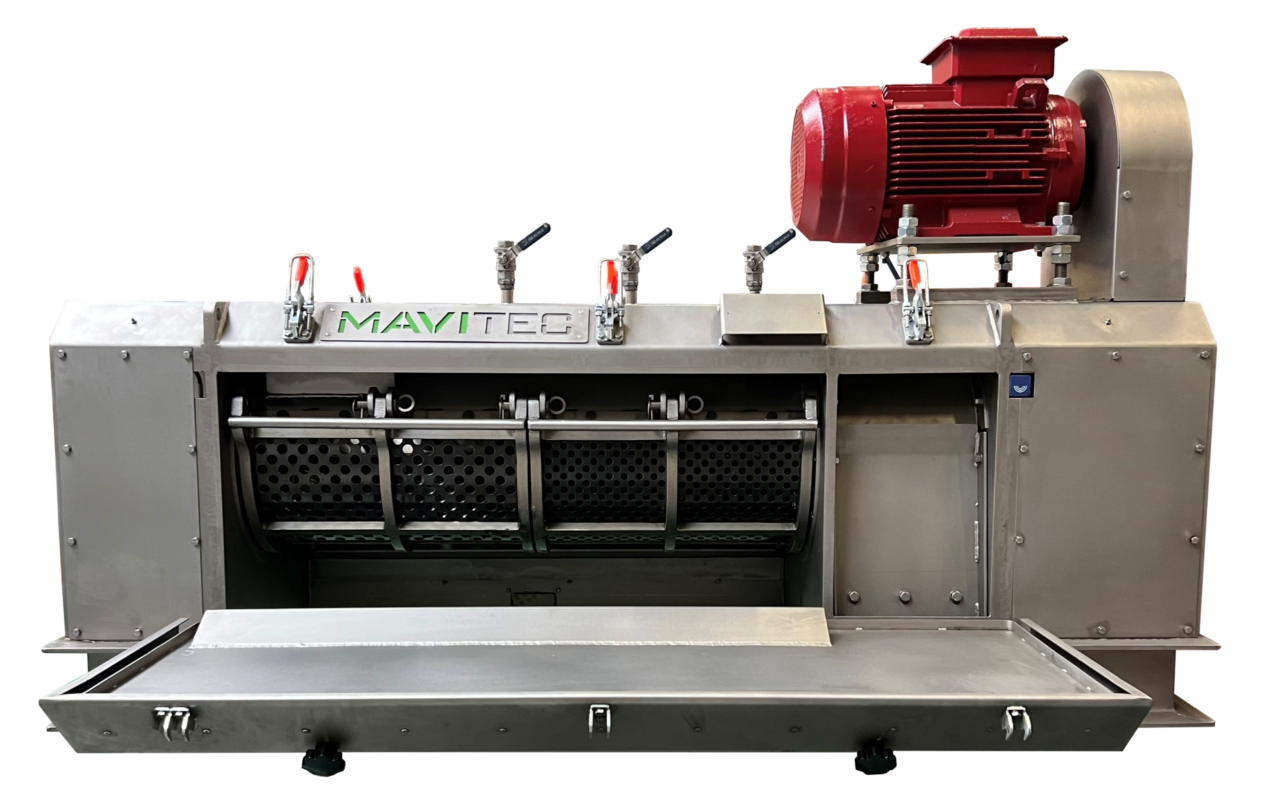

Mavitec Green Energy offers a wide range of solutions for handling factory rejects. The Paddle Depacker is a complete food waste & depackaging solution that separates the organic fraction from the packaging. This high capacity machine (15-30 m3 per hour) produces a very clean organic output that is extremely suitable for use in biogas installations. The Paddle Depacker has a robust and tough design with easy maintenance options. These are critical when processing unwanted leftover material from production processes. The machine produces a clean packaging fraction as well. The Paddle Depacker is also available in a compact size model (1-5 m3 per hour).