In 2024, one of Türkiye’s largest ice cream producers needed a practical solution for handling waste resulting from misproduction. This included ice cream mixed with sticks, lids, and plastic packaging. With limited disposal options in the area, the company searched for an on-site system that could separate these mixed waste streams efficiently and in an environmentally responsible way.

Reliable separation of packaging and organics

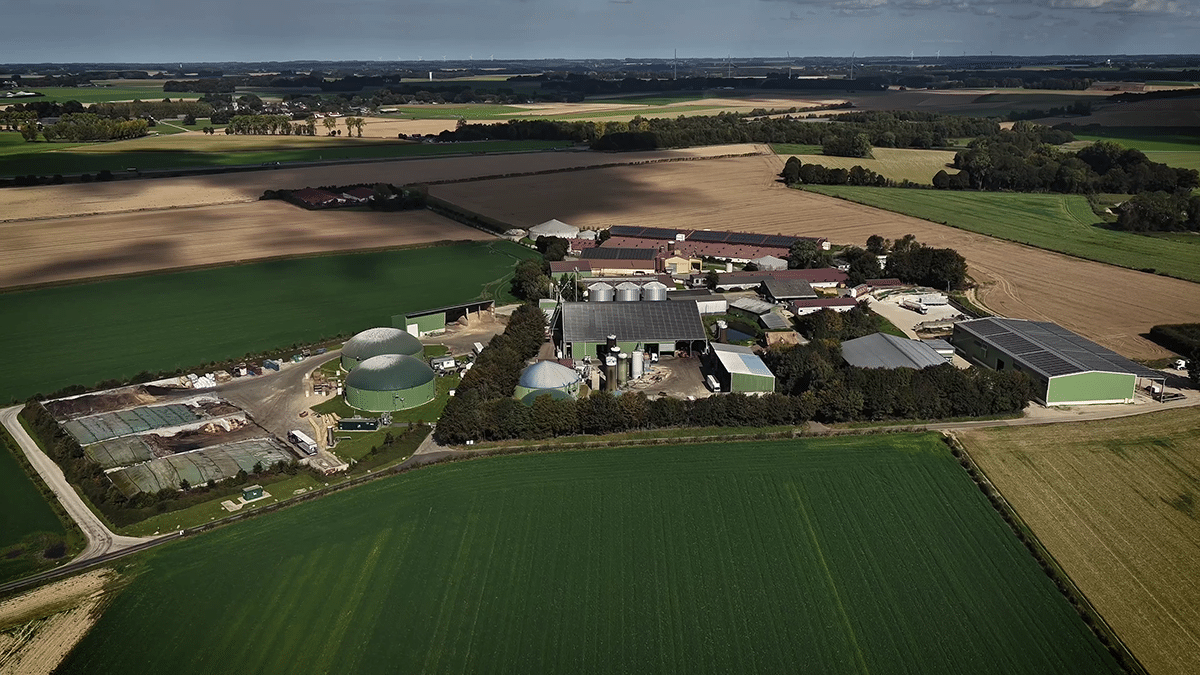

To address the challenge, the company installed the Paddle Depacker Model S. This compact depackaging unit processes approximately 3 tons of waste ice cream per day. It separates packaging from the organic material with high precision, achieving an organic output purity of more than 99.7%. The result is a clean, pumpable material that is suitable for use in biogas installations.

Compact, user-friendly and efficient

Thanks to its space-saving design and ease of operation, the Paddle Depacker S has become an integral part of the daily process. It offers a consistent and reliable way to prepare organic waste for further processing, helping the company reduce its environmental impact while streamlining operations.

This case shows how specific and challenging waste streams—such as misproduced ice cream with packaging—can be managed effectively on-site.

Looking for a smart way to handle your organic or packaged production waste?

Whether you’re dealing with production waste, expired goods, or mixed packaged organics, we’re happy to advise on the right setup for your process. Get in touch to explore how Mavitec Green Energy can support your waste processing challenges with the right solutions.