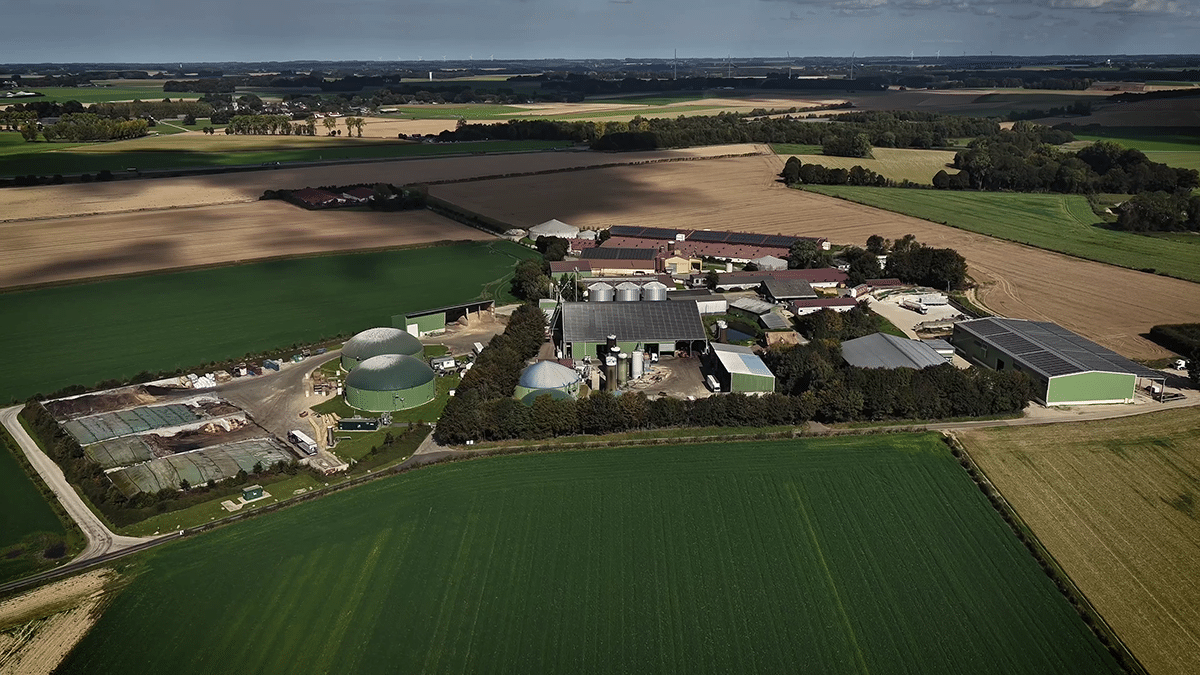

In Courtenay, France, Mavitec successfully completed the installation of a complete depackaging line. This installation includes a Double Paddle Depacker Line, equipped with two Paddle Washers and a 2-cylinder piston pump, developed for high-capacity processing of food waste. Designed to process food waste from supermarkets, restaurants, and packaged products such as bottled beverages, the installation handles up to 30 m³ per hour of mixed materials.

Tailor-Made Setup for Complex Waste Streams

This installation was developed to process both wet and dry food waste simultaneously. With a combination of depacking and cleaning technologies, the line separates packaging from organic content efficiently, resulting in a clean organic output suitable for further processing such as anaerobic digestion.

Engineered for Performance

The system was custom-designed to meet specific requirements. Key aspects such as vibration control, conveyor flow, fluid management, and system integration were fine-tuned during commissioning to ensure stable and reliable performance. These optimizations led to improved machine stability, smoother material flow, and seamless automation — even when processing large volumes of packaged materials like plastic bottles.

Operational Success

The installation demonstrates Mavitec’s ability to deliver advanced, tailor-made solutions for challenging waste streams. The line is now operating at full capacity and has significantly improved the efficiency of food waste processing on site.

Would you like to learn more about our depackaging solutions or schedule a reference visit? Get in touch — we’re happy to help.