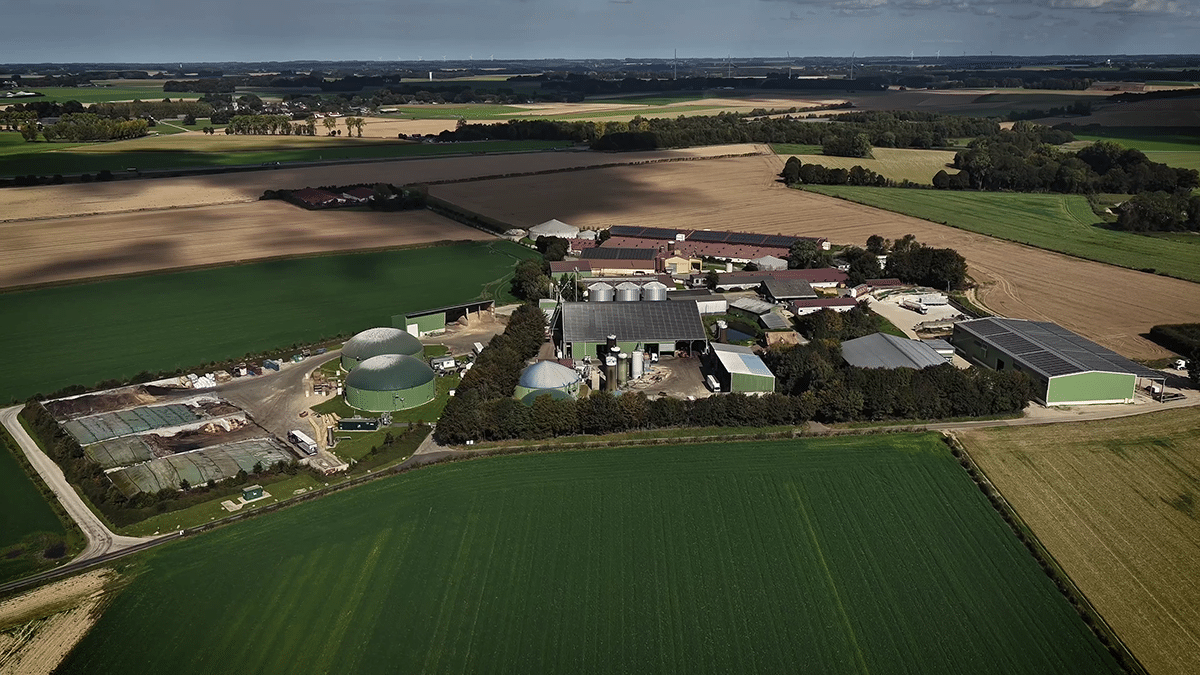

A biogas plant in Poland, processing approximately 35,000 tons of food and agricultural waste annually, faced a significant operational challenge. A substantial portion of its incoming material – primarily supermarket and mixed organic waste – was heavily contaminated with plastic packaging, bags and bottles. Efficient separation of this non-organic material was essential to maintain performance and sustainability. Without it, the waste would either reduce biogas quality or require costly, energy-intensive processing.

Testing the Paddle Depacker solution

To tackle this challenge, the plant turned to Mavitec Green Energy and tested the Paddle Depacker, a mobile depackaging unit designed to separate packaging from organic waste. This rental unit allowed the plant to test the solution under real operating conditions, using its own specific waste stream, without any upfront investment.

The results were promising. The system produced a high-quality organic slurry suitable for anaerobic digestion. At the same time, the amount of organic material remaining in the plastic fraction was greatly reduced. This not only improved the input for the biogas digester, but also lowered disposal costs due to lighter, cleaner waste.

A permanent depackaging installation

Following the successful trial, the plant decided to install a permanent Paddle Depacker system. The full setup now includes a 8m³ front-loader storage hopper with twin screw feeding system, Paddle Depacker and organic piston pumping system, with a capacity of up to 30m³ per hour.

The system ensures that only high-purity organic material, with a verified purity level of 99.7%, enters the digester. This cleaner organic slurry does not only enhance biogas yield, but also supports a more stable, efficient plant operations.

Higher efficiency, cleaner energy

With the new setup, the plant has significantly improved its efficiency. It now produces 1,000 kW of electricity and 1,600 kW of heat around the clock. Beyond improved energy output, the plant benefits from more consistent operations, lower processing costs and stronger environmental performance. This case illustrates how targeted technological solutions can help biogas facilities handle increasingly complex waste streams, while improving operational efficiency and supporting environmental objectives.

Discover what’s possible for your plant

Mavitec’s work in Poland shows what’s possible with smarter food waste handling. Whether you’re looking to improve biogas yield, reduce contamination or streamline your processing, we’re happy to think along. Contact our sales team to explore how we can help optimize your biogas operations.