Four Sites in Four Days – The Paddle Depacker V3 on the Road

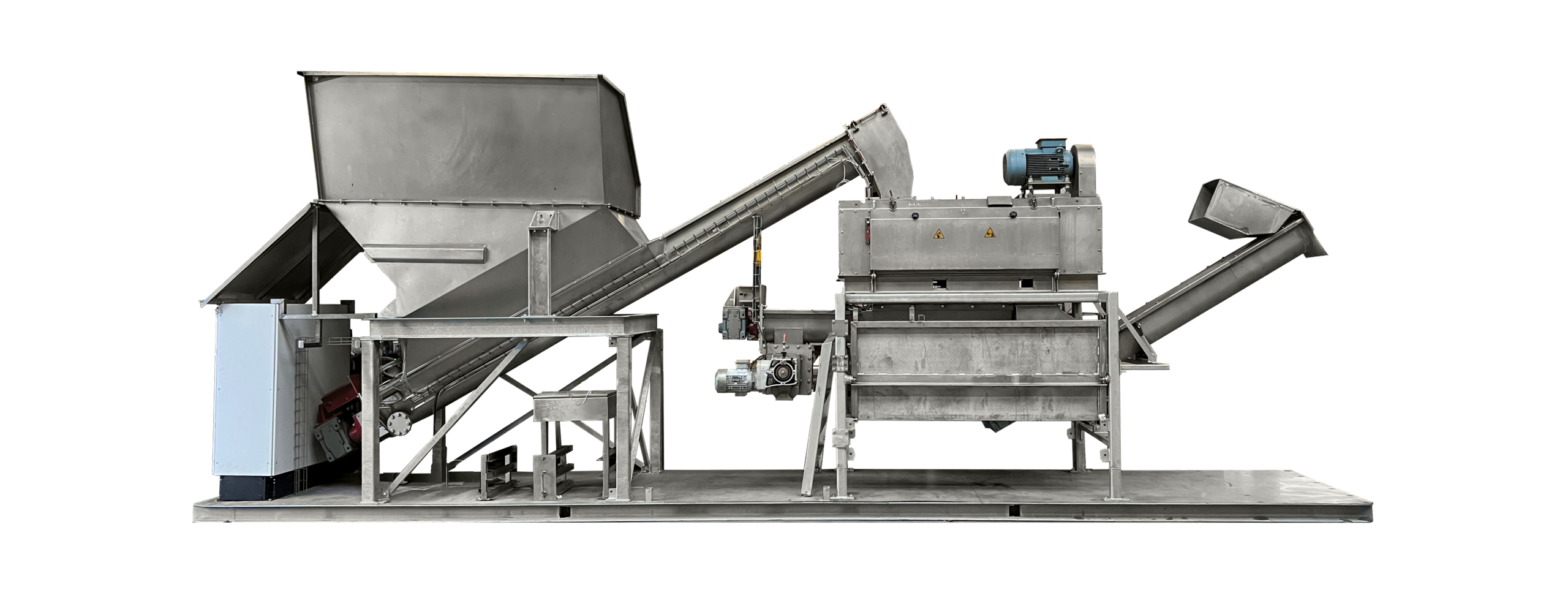

After its successful introduction in Spain and Portugal, the mobile Paddle Depacker V3 continued its route through Europe. Recently, the roadshow visited four different companies in Eastern Europe for four consecutive days of on-site testing. Each location presented its own materials, market conditions and expectations, providing a clear view of how the V3 performs in practice with reliable, high-quality output. The objective was straightforward: demonstrate the quality of the results directly on site.

Day 1 – Existing customer explores upgrade for higher capacity

The first visit was to a long-term Mavitec customer currently operating a Paddle Depacker Model S with a capacity of 1–5 m³ of material per hour. With increasing material volumes and the need for higher throughput, the on-site test with the Roadshow V3 offered valuable insight into the next step. The results showed the same familiar depackaging concept, but now with significantly higher capacity: 15–30 m³ of material per hour*, while maintaining the consistently high output quality the customer is accustomed to. Based on these test results, the customer expressed clear interest in upgrading to a larger model in the near future.

Days 2–4 – New prospects testing their own challenging materials

The following days focused on potential new customers. Each company tested a different mix of input materials, ranging from organic household waste streams and supermarket returns to mono-streams, factory rejects, and other general food waste. Across all three visits, the V3 produced a clean organic soup with purity levels of up to 99.7%. This consistent output quality gave each company a clear picture of how their materials can be processed on site, and the teams were clearly impressed by the reliability of the results.

Applicable to a broad range of industries – all aiming to improve depackaging performance

The test week highlighted another core strength of the Roadshow V3: its verstatility across different sectors. The companies involved represented industries where clean organic output and reliable depackaging are essential, including:

- Biogas plants aiming to improve input quality and increase yields

- Agricultural operators processing organic material streams

- Waste and recycling companies seeking dependable depackaging technology

- Food producers and retailers evaluating solutions for returned or off-spec products

Despite the differences in materials and challenges at each site, the mobile Paddle Depacker V3 demonstrated stable performance with consistently high-quality output across all tests.

Supported by our local partner

Throughout the week, the Roadshow was supported by our local partner Elkoplast, who provided logistical coordination, local market expertise, and on-site technical assistance. Their involvement allowed customers to ask questions in their own language and receive immediate guidance during the tests.

The purpose of the Roadshow: testing the customer’s own material

The Roadshow V3 is designed to demonstrate performance under real conditions: at your location, with your own materials, and with the same high-quality output delivered at sites across Europe. This approach gives customers clear understanding of how the V3 handles their specific streams before making an investment.

Interested in testing your own material?

Our Roadshow V3 truck can visit your site for a live demonstration. Contact our team to learn more about the possibilities, or visit our página de aluguel to explore our range of testing machines.