Mavitec solution for packaged organic waste in France

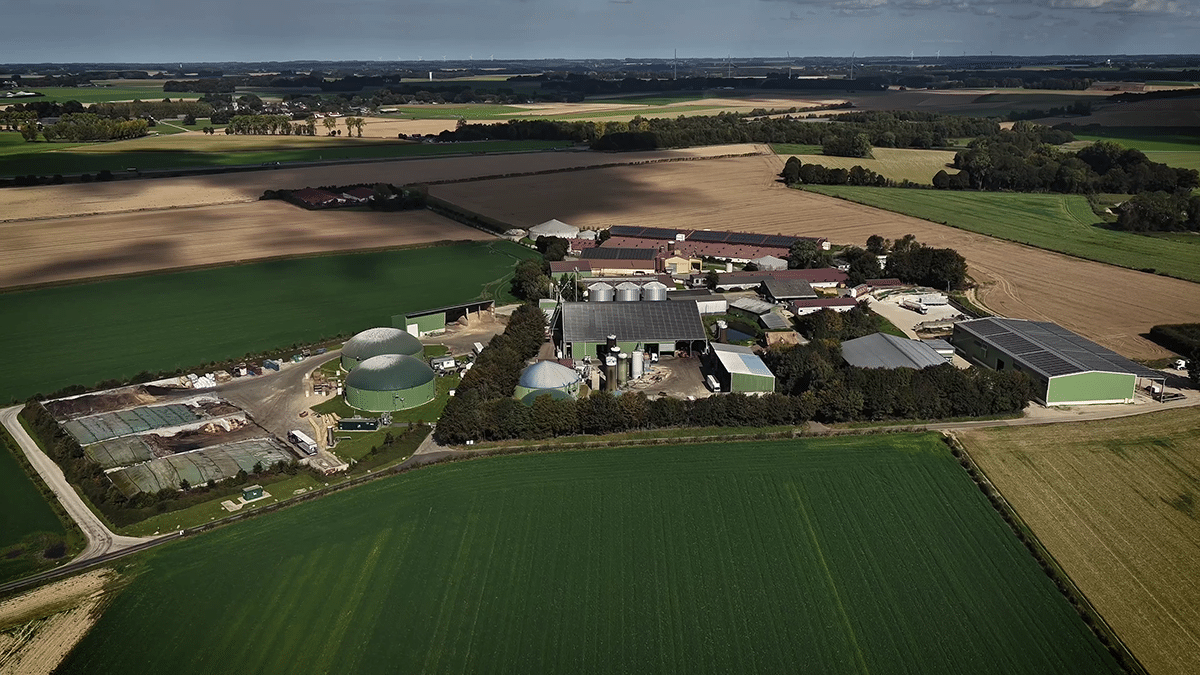

In Normandy, France, Mavitec Green Energy supplied a complete preprocessing line to turn complex, packaged organic waste into clean input for anaerobic digestion. The installation supports a municipality-led collection program and a local biogas plant that needed a scalable setup to protect digester performance and ensure a clean return to soil.

The municipality of Costrobert launched a pilot for separate organic waste collection in 2022, anticipating the national obligation that became mandatory on 1 January 2024. As volumes increased, the biogas plant in Cléville quickly outgrew its basic depackaging approach. The next step was clear: upgrade to an integrated line built around purity, stability and circular valorisation. The biogas plant is a returning Mavitec customer, expanding its setup based on earlier positive experiences with our equipment.

The challenge: clean organics from complex organic waste streams

The incoming organic waste consists of material from households, supermarkets and food industry sources. A large share of these streams arrives packaged, which makes contamination hard to avoid and purity harder to control.

The objective was to separate packaging efficiently, produce a high-quality organic fraction for stable biogas production and meet strict purity requirements. At the same time, the plant aimed to improve the packaging fraction so it could be directed to recycling streams.

Met de paddle depacker komen we al op wetgeving, maar klant wilde kwaliteit van de soep nog beter. en daarom orgapuur systeem.

The Mavitec Green Energy installation

The process starts with the Mavitec Paddle Depacker, which separates packaging from organic material and produces a continuous, pumpable organic slurry (“soup”) for anaerobic digestion. A hydrocyclone system then removes heavy contaminants such as glass, shells and stones, helping to protect downstream equipment and support stable digestion performance.

Where required, the slurry is hygienised (70 °C for one hour) and ground to 12 mm. As an extra polishing step, the slurry can be further filtered through an Orgapure line to remove remaining fine impurities. In parallel, the separated packaging fraction is processed by a Mavitec Lavadora de pás to wash and dewater the material, improving handling and supporting recycling.

The result is a robust depackaging and conditioning process that delivers a clean organic fraction for biogas production and a packaging fraction ready for further recycling steps.

The result: clean input, stable digestion and circular valorisation

The installation produces a high-purity organic slurry, with microplastics reduced to non-detectable levels. This supports stable anaerobic digestion and contributes to a clean digestate suitable for agricultural use. With cleaner, more consistent feedstock, the plant benefits from reliable biogas production performance. At the same time, washed and dewatered packaging materials can be directed to recycling streams, supporting circular economy goals and regulatory compliance.

This project demonstrates how Mavitec Green Energy helps unlock the full value of organic waste: converting it into renewable energy while closing material loops. For this customer, it is also a natural next step in a longer collaboration with Mavitec, scaling up as volumes and quality requirements increased.

Ready to optimize your organic waste processing?

Mavitec Green Energy supports biogas operators and municipalities with smart, reliable preprocessing solutions for complex organic waste streams. Contate-Nos to discover how we can help you turn organic waste into clean biogas and recyclable materials.